تزریق پلاستیک و قالب سازی آذین پلاست فناوران آسیا

اولویت ما در آذین پلاست فناوران آسیا تولید قطعاتی با کیفیت است که مطابق با سلیقه مشتریان بوده و بتواند نیاز آن ها را برطرف کند.

طراحی محصول

طراحی محصول توسط متخصصی ماهر و زبده با استفاده از بروز ترین متد ها

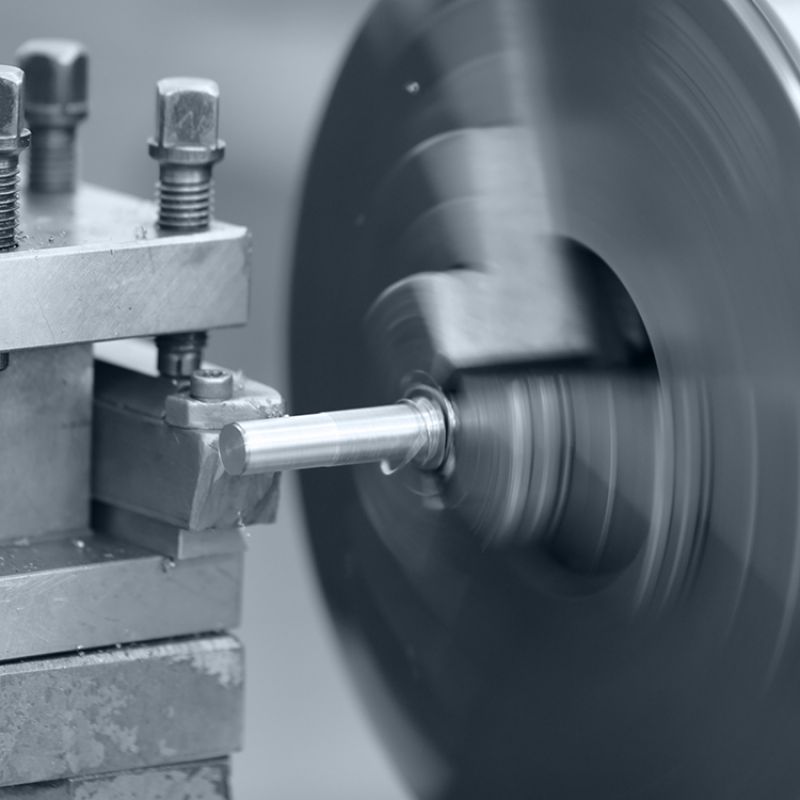

طراحی و ساخت قالب

طراحی قالب و انجام خدمات تزریق پلاستیک با استفاده از ابزارهای مدرن و بهروز دنیا انجام میشود. استفاده از متریال فوق العاده با کیفیت برای ساخت قطعات پلاستیکی و طراحی قالب، جزو اهداف اصلی کارشناسان و متخصصان این مجموعه است. در فرایند طراحی قالب ها از بروز ترین متد های DFM و DFA استفاده می شود. پس از آن طرح نهایی با هدف پیش بینی کلیه موارد و نکات تولید ناب، در کمیته چند تخصصی بررسی می شود. پس از تایید طراحی، کلیه اجزا قالب توسط پیشرفته ترین روش ها، ساخته و با دقت بسیار بالایی توسط قالبساز مونتاژ می شود.

تولید محصول

فرآیند تولید با بهره گیری از دستگاه های روز دنیا انجام میشود. آذین پلاست با استفاده از تجربه و دانش متخصصان خود و به کارگیری دستگاههای مجهز، ظرفیت ساخت قالب های مختلف پلاستیکی را دارد. این مجموعه برنامه کاری و اهداف خود را در ابتدا برای جلب رضایت مشتریان تنظیم می کند و از مواد اولیه بسیار مرغوب و قابل رقابت با محصولات پلاستیکی جهانی هستند، استفاده می کند.

مواد اولیه در تزریق پلاستیک

انتخاب مواد اولیه در فرایند تزریق پلاستیک اهمیت زیادی دارد، زیرا بر ویژگیهای نهایی قطعه تأثیرگذار است. مهمترین مواد پلاستیکی که در این فرایند مورد استفاده قرار میگیرند شامل:

| مواد | ویژگی |

|---|---|

پلیپروپیلن (PP) | سبک، مقاوم و ارزانقیمت |

پلیاتیلن (PE) | انعطافپذیر و مقاوم در برابر ضربه |

پلیاستایرن (PS) | اقتصادی و مناسب برای قطعاتی که نیاز به دقت بالا ندارند |

پلیآمید (نایلون) | مقاوم در برابر ساییدگی و دما |

پلیاتیلنترفتالات (PET) | مناسب برای قطعات شفاف و مقاوم |

ویژگیهای تزریق پلاستیک آذین پلاست

-

استفاده از مدرنترین تکنولوژیها در دستگاهها

-

استفاده از متریال مرغوب و با کیفیت اولیه

-

پاسخگویی به مشتریان

-

انجام وظایف به بهترین نحو برای جلب رضایت مشتریان

ویژگیهای قالب های ساخته شده در آذین پلاست

مجموعه آذین پلاست اقدام به ساخت بهترین محصولات با بهترین استراتژی کرده است و به همین دلیل، توانسته عنوان بزرگترین کارخانه تزریق پلاستیک گروه صنعتی آذین خودرو را از آن خود کند. این ویژگیها به شرح زیر هستند:

-

استفاده از استراتژی قدرتمند و طراحی پیش بینانه ریسک های احتمالی در طراحی قالب و استفاده از متد DFM و DFA در طراحی

-

بالا بودن کیفیت متریال مورد استفاده

-

ساخت اجزا و مونتاژ قالب با بالاترین تکنولوژی و بهره بری از تجربه بالا کارکنان

-

تست دقیق محصولات ساخته شده

-

دریافت بازخورد از مشتریان و بهبود

مزایای خدمات تزریق پلاستیک در آذین پلاست

در بالا به ویژگی های قالب های ساخته شده ما آشنا شدید، در ادامه به جزئیات مزایای استفاده از خدمات تزریق پلاستیک مجموعه آذین پلاست می پردازیم:

-

۱. دقت و کیفیت بالا: آذین پلاست با بهرهگیری از دستگاههای مدرن، قطعات پلاستیکی را با بالاترین دقت و کیفیت تولید میکند.

-

۲. استفاده از مواد اولیه مرغوب: این مجموعه از پلیمرهای باکیفیت استفاده میکند که موجب دوام و استحکام بیشتر قطعات میشود.

-

۳. سرعت و صرفهجویی در هزینه: فرآیندهای بهینهشده باعث کاهش هزینههای تولید و تسریع در تحویل سفارشات میشود.

-

۴. امکان ساخت قطعات سفارشی: آذین پلاست خدمات قالبسازی و ساخت قطعات متناسب با نیاز مشتری را ارائه میدهد.

-

۵. رعایت استانداردهای کیفی: تمامی قطعات با نظارت دقیق و مطابق با استانداردهای بینالمللی ساخته میشوند.

-

۶. پشتیبانی و مشاوره تخصصی: تیم مجرب آذین پلاست در تمامی مراحل از طراحی تا ساخت، راهنماییهای لازم را ارائه میدهد.

با انتخاب آذین پلاست، میتوانید از خدمات حرفهای و قطعات باکیفیت بهرهمند شوید.

مزایای استفاده از خدمات قالب سازی پلاستیک آذین پلاست

| مرحله | توضیحات |

|---|---|

ارائه ایدههای نوین | تیم خلاق و باتجربه آذین پلاست ایدههای نوآورانه و کارآمدی برای طراحی و ساخت قالبهای پلاستیکی ارائه میدهد. |

طراحی قالب | با استفاده از نرمافزارهای پیشرفته و استانداردهای جهانی، طراحی دقیق قالبها توسط متخصصان مجموعه انجام میشود. |

DFM/DFA | استفاده از متد DFM/DFA با هدف بهبود و افزایش کارایی قالب و محصول |

ساخت قالب | با بهرهگیری از نقشههای دقیق و ابزارهای پیشرفته، قالبهای پلاستیکی با دقت و مهارت بالا ساخته میشوند. |

تست و اصلاح قالب | پس از ساخت، نمونهگیری و تستهای اولیه انجام شده و اصلاحات لازم برای بهبود عملکرد قالب اعمال میشود. |

تولید انبوه | پس از تأیید نهایی، فرآیند تولید انبوه آغاز شده و محصولات با کیفیت بالا و مطابق با استانداردهای موردنظر تولید میشوند. |

هزینه ساخت قالب تزریق پلاستیک تحت تأثیر چند عامل اصلی قرار دارد که به شرح زیر است:

پیچیدگی طراحی قالب

طراحی پیچیدهتر قالب، مانند قطعات با هندسه خاص یا چندحفرهای، نیاز به دقت و تخصص بیشتری دارد و باعث افزایش هزینه میشود..در ضمن با توجه به پیش بینی نقاط و مواضع حساس در قالب، این مواضع بصورت اینسرت در نظر گرفته می شوند تا در صورت آسیب کمترین هزینه و زمان را داشته باشد.

نوع و اندازه قالب

قالبهای بزرگتر یا قالبهایی که برای تولید قطعات حجیم طراحی شدهاند، نیاز به مواد بیشتر و زمان بیشتری برای ساخت دارند. این امر منجر به افزایش هزینه ساخت قالب تزریق پلاستیک میشود.

نوع ماده پلاستیکی

استفاده از پلاستیکهای خاص مانند پلیکربنات یا نایلون که نیاز به قالبهای مقاومتر و دقیقتر دارند، موجب افزایش هزینه ساخت قالب تزریق پلاستیک میشود.

تعداد تولیدات

برای تولید انبوه، هزینه ساخت قالب تزریق پلاستیک ممکن است کاهش یابد زیرا هزینههای ثابت قالب بین قطعات تقسیم میشود. اما در تولید کمتعداد، قیمت قالب تزریق پلاستیک بهطور قابل توجهی افزایش مییابد.

فناوری ساخت و دقت ماشینکاری

استفاده از ماشین های CNCفرز و تراش و EDM باعث افزایش دقت و کیفیت قالب میشود که روی قیمت قالب تزریق پلاستیک تأثیر میگذارد.

Developer & Designer | Hossein Donyadideh